Golf course and large commercial irrigation control systems will have a large amount of communication and/or control wire. The additional protection of a ground bonding wire may help when fighting lighting strikes and electrolysis.

Not all irrigation designers will specify ground bonding or shield wires and many courses choose not to install it to cut costs.

Not all irrigation designers will specify ground bonding or shield wires and many courses choose not to install it to cut costs.

Irrigation manufacturers do not ask for ground bonding to protect their equipment.

One major wire manufacturer does require bond-shield wires in order to protect their grounding electrodes.

So how important is it? First a short description on what ground bonding shielding wire is.

Ground Bonding and Shielding Wire

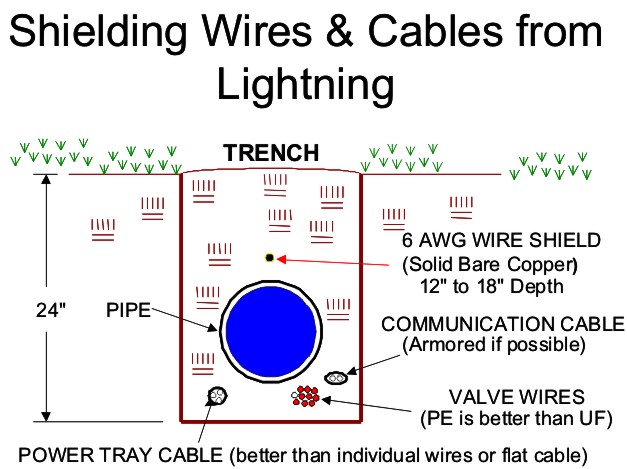

Typically a #10, #8 or #6 gauge bare copper wire will be installed 12 inches below grade in any irrigation trenches that include wire runs.

The bond wire will then attach to every grounding electrode (rods or plates) installed on the course. A twofold purpose results;

Shielding

The bond wire acts as shield to intercept electro-magnetic power from lightning strikes and channel some or all of it to the ground electrodes. The control, power, and communication wire installed deeper below is then “shielded” from the lightning current.

Since electrical surges are induced into a buried wire as lightning electro-magnetic energy passes by, this helps reduce surges that can damage the irrigation control components or the wire itself.

By way of some insight, a lightning strike can cause energy to travel up to 10 or miles. The volume of electrical energy is off the charts or at least beyond the realm of what most of us can comprehend. Thousands of amperes can be induced into a wire. Enough to melt the wire and definitely enough to burn circuit boards and transformers.

The purpose of the grounding network is to give surges somewhere else to go instead of hitting our control equipment. The ground path has to be less restrictive than the equipment. The path of least resistance.

Bonding

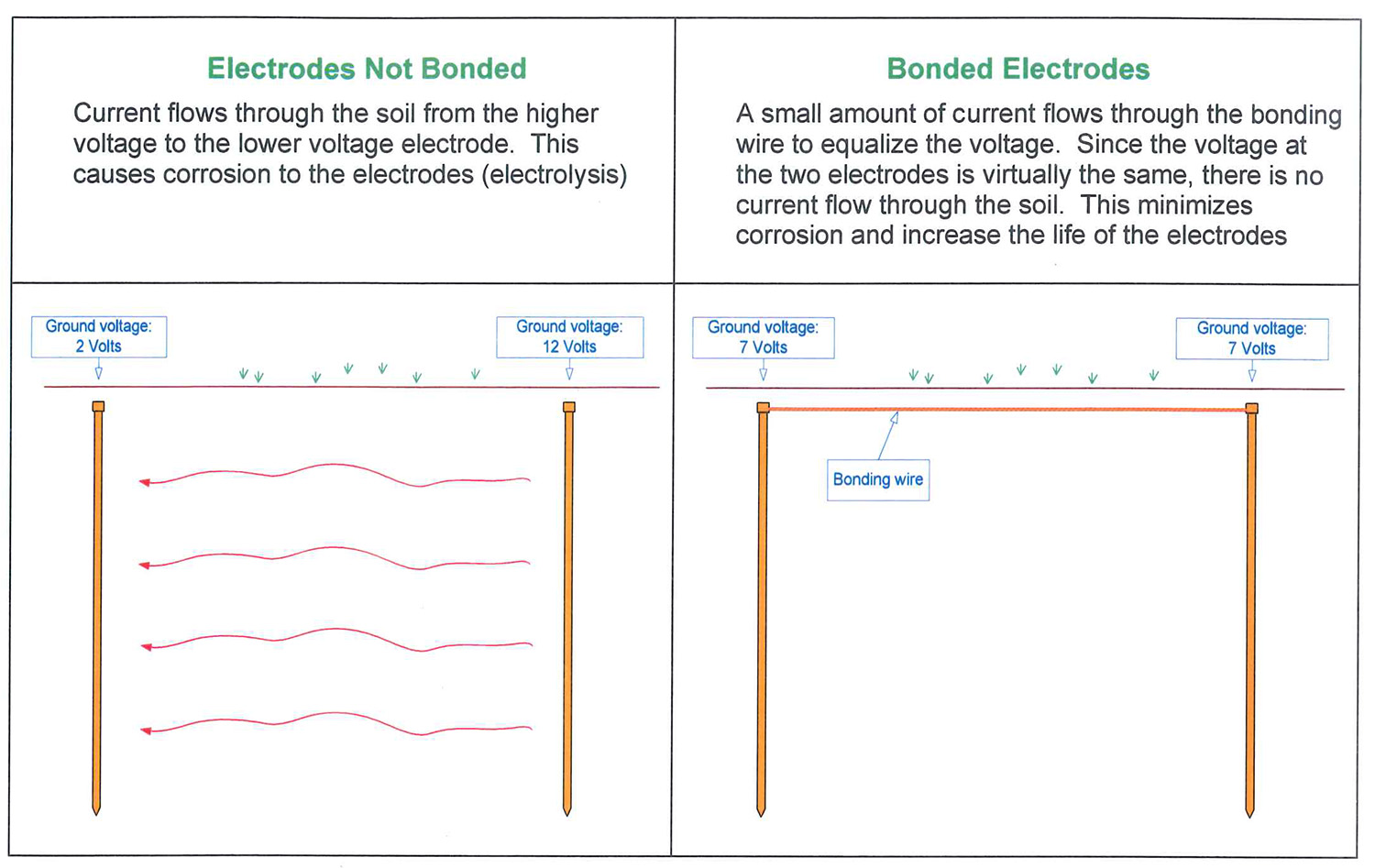

Most golf and large irrigation systems have several grounding points along their wire paths. Each ground point may one or more electrodes installed at a unique place on the property. Because of differences in soil type and moisture, the electrodes likely have slight differences in electrical potential (voltage).

Voltage differences in the ground are aggravated by the earth’s rotation and atmospheric activity, which creates static electrical charges.

The result is the flow of electrical power through the soil from areas of higher potential to areas with lower. A condition causing corrosive degeneration of the grounding wire and electrodes. Commonly called electrolysis.

See the diagram. Where the voltage in the ground is different, we get electrolysis. Where the voltage is the same we do not. By tying the two electrodes together with a bond wire, the voltage is equalized. Thus no voltage flows through soil and no electrolysis.

Ground Bonding Benefits

- Protects the grounding system from degradation via electrolysis.

- Shields the communication wire from lighting surges.

- Provides a more robust grounding network.

For the extra cost, a ground bonding shielding wire extends the life of the irrigation component surge protection. Surge suppression circuitry is weakened every time it takes a hit. Reducing the number and strength of lightning surges will keep the surge protection alive longer. That will help assure the control equipment is protected.