As simple as it seems, it takes some skill to reliably make good threaded fitting joints. Especially with plastic fittings.

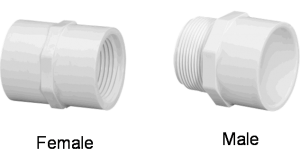

First, understand there are male and female fittings. The most prevalent danger is splitting the female fitting.

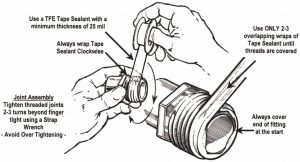

The common cause of splitting female fittings is either over tightening and/or too much Teflon tape. See the assembly diagram.

Note the specification, which all plastic pipe fitting manufactures build to, states to tighten by hand and then give it two to three turns past hand tight with a wrench. A strap wrench is suggested to avoid damaging the plastic, but most use channel locks or pipe wrenches. Just be careful so you do not warp or scrape the fittings.

The female socket is tapered so the connection becomes tighter the deeper into the fitting the male thread are inserted. Tightening past two to three turns applies too much external force and that’s what causes the female fitting to split. Many feel they need to fully bury the male threads to avoid leakage. That is not the case, they are in fact hastening an eventual failure.

Also note, the specification is for no more than two to three wraps of Teflon tape. Teflon tape is a lubricant. Many believe it helps seal the fitting, which is minor at best. It’s job is to allow you to sufficiently tighten the joint. However, more than three wraps adds enough breadth that again you can split the female fitting.

Often both too much Teflon tape and over tightening are applied. And people wonder why their joints leak or fail!