Doing the right thing, or even the “extra” thing, is never wrong. It sets you and your jobs apart from every other contractor. Many best practices take little extra time, and your customers will love you for it. It makes them WANT to refer you to their friends and family because they know that you’ll take good care of them.

Code related requirements are not considered “best practices” because they should not be considered “optional.” Designers and installers should have these requirements integrated into their work for the requirements that they are. Code related background information is included below for reference and because of the nature of regulations it may be dated or incomplete for your locality. Please verify local requirements with the proper authorities in your area.

National Electrical Code

The National Electrical Code (NEC) has as its purpose the “practical safeguarding of persons and property from hazards arising from the use of electricity.” The NEC is written by the NFPA (National Fire Protection Association), a U.S. trade association group founded in 1896, to create standards and codes for usage and adoption by local governments. One of its publications is the NFPA 70, National Electrical Code.

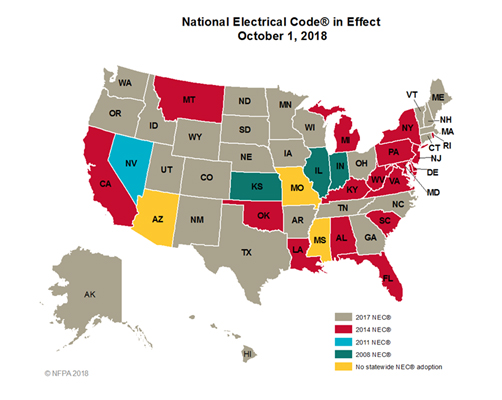

While the majority of the NEC is directed at line voltage (120V and above) related products and installations, low voltage (30V and below) products and installations are not exempt from following the code if the state or local governmental jurisdiction has implemented it. While the NFPA periodically releases updated NEC standards, local jurisdictions have the freedom to choose if they want to implement the NEC and what version.

Some local governments require permits for low voltage lighting but rarely inspect the jobs, while others do require inspection. Some states will establish a base NEC standard statewide, and no local jurisdiction may allow requirements below that established level, but they can choose to make local requirements more stringent. The contractor should confirm this information and inform their customers when needed. Ultimately, it is the contractor’s responsibility to know and adhere to these requirements or bear the safety and legal consequences.

Here’s a listing of NEC Articles that may be applicable to contractors working with low voltage lighting (and irrigation) systems:

| Article 90 | Introduction |

| Article 100 | Definitions |

| Article 110 | Requirements for Electrical Installations |

| Article 210 | Branch Circuits |

| Article 250 | Grounding and Bonding |

| Article 300 | Wiring Methods |

| Article 310 | Conductors for General Wiring |

| Article 362 | Electrical Nonmetallic Tubing |

| Article 400 | Flexible Cords & Cables |

| Article 406 | Receptacles, Cord Connectors and Attachment Plugs (Caps) |

| Article 411 | Lighting Systems Operating at 30 Volts or Less |

| Article 590 | Temporary Installations |

| Article 680 | Swimming Pools, Fountains & Similar Installations |

| Article 725 | Class 1, Class 2, and Class 3 Remote-Control, Signaling, and Power-Limited Circuits |

Overview of NEC Rules for Low Voltage Lighting

Transformers:

-Minimum mounting height of 12 inches above grade (more information below).

-Power cord may not be cut off or hardwired; must be plugged into an outlet.

-Power cord must be plugged into a GFCI outlet with a functioning WIU (While In Use) “bubble” cover.

(GFCI – Ground Fault Interrupter Circuit).

-Transformers should not be plugged into extension cords.

-Each transformer has a label indicating its maximum amperage capacity. The load should never exceed that number. (This load is calculable when a designer is laying out the design, thus allowing the designer / specifier the ability to size the correct wire for a given wire run and the correct transformer.) Maximum Amperage is calculated using the following formula: Watts / Volts = Amps;

Transformer Size / 120V = Max Amp Load.

Another wise practice to implement is to factor in a buffer when sizing transformers and wire gauge selections. It gives you more flexibility if an installation changes in the field or you have to add a few additional fixtures.

| Transformer Size | Formula | Amperage Maximum |

| 75W | 75W / 120V = | 0.625A |

| 100W | 100W / 120V = | 0.833A |

| 200W | 200W / 120V = | 1.67A |

| 300W | 300W / 120V = | 2.5A |

| 600W | 600W / 120V = | 5.0A |

| 900W | 900W / 120V = | 7.5A |

| 1200W | 1200W / 120V = | 10.0A |

Transformers

Transformers are required to be mounted twelve inches above grade to prevent water from getting into the housing. They can be mounted higher than 12 inches, but not lower. If you’re mounting them in a flood/snow prone area, then mount them higher to protect them.

Conduit that is physically connected to the bottom plate of the transformer may be connected with a slip by thread fitting and a lock nut. Conduit should be a minimum of 18 inches long (6 inches below grade and 12 inches above grade). It can be longer if needed based on the mounting height of the transformer. Contractors can also install a “sweep” pipe at the bottom of the conduit (underground) to prevent the conduit from settling on top of the wire and possibly nicking or cutting the wire jacket. Conduit should always be grey in color thus identifying it as electrical conduit.

Transformers will always have at least two screws either both at the top or one each top/bottom to hold the transformer securely in place. Make sure to use both screws to keep the transformer from moving.

It is recommended to mount transformer(s) on metal or wooden posts that are securely positioned in the ground – plumb and level, and that can handle the weight of a transformer. If using a wooden post, a 4”x4” post of treated lumber is needed at a minimum. Do not mount transformers on houses constructed of stucco, dryvit, aluminum siding, vinyl siding, or thin brick or thin stone facades. The weight of the transformer or the heat it generates can compromise the materials.

Contractors must call 811 (utility protection service) prior to installing any job. It is strongly recommended that this task not be left to the property owners. The fines will be charged to the company / person that damages the utility.