The outdoors offers a variety of interesting things to illuminate so it stands to reason that those variations require an assortment of fixtures in order to bring a design to life. While choosing the right fixture and the right light output is important, sometimes a change in those options is forced on the lighting designer because you don’t have a place to mount the fixture in order to accomplish your lighting goals. Another challenge is that you might have the mounting surface you need, but that angle casts glare in an undesirable direction (towards a seating area, into the neighbor’s house, into a window, etc.) so you might not be able to use it.

So, knowing the various accessory mounting options you have at your disposal can not only save your design, but it also saves you time, which in turn saves you money.

Ground Stakes

Most contractors are aware of the typical 8-inch stake that comes with most ground mounted fixtures, but some manufacturers offer a slightly longer version for more stability / less ground heave. Another quick tip for service calls is to keep slit-top stakes in your service vehicle. These handy stakes eliminate the need to cut and splice a wire just to replace a stake. Some manufacturers offer stamped metal stakes that cut into the ground much more easily than a plastic stake; they can be purchased separately.

The “big brother” to these ground stakes is the Power Post. These are typically listed for 12-volt or 120-volt use, and they must be “dug in.” Meaning that you’ll need a post-hole shovel or a small auger to make a 20” x 6” hole, attach the fixture to the top of Power Post, connect the wires with a proper silicone or grease-filled wire nut, put it down inside the hole plumb and level, lay the wire in the trench, and backfill and tamp so the stake and fixture are stable. Since the stake body is a 3-inch piece of PVC pipe, it also serves as a junction box for your connections. The top caps of power posts are removable if you need access to the connections for some reason.

Concrete Pour Kits & Core-Drill Sleeves

Just about every lighting manufacturer out there makes some sort of concrete pour kit for in-grade fixtures. They can also be used in soil if needed. The thing to be aware of is that these kits tend to be fixture-specific and won’t necessarily mix-and-match with other fixtures or brands. Some fixtures will fit inside a field-cut section of standard pipe, while others have specialty sleeves. Make sure to read the installation directions for these kits prior to using them so that you get them installed at the proper height and conduit is run properly to/between them. It’s also helpful to pre-install the wire before you do the concrete pour. If a cover doesn’t come with a kit, create one out of foam, newspaper, duct tape, etc. so that concrete doesn’t get inside the sleeve.

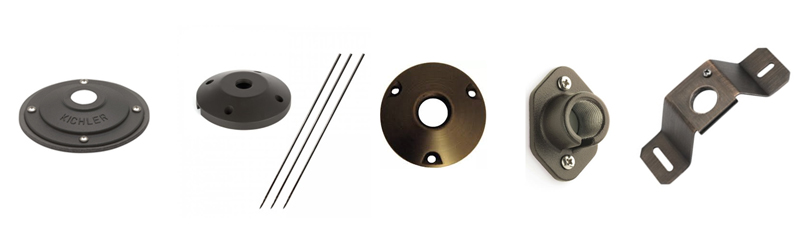

Surface Mounts

Surface brackets can be used to mount any thread-base fixture to a surface where you can’t use a stake. Examples include mounting a down light to a pergola, mounting an up light to a wall, or even mounting a path light to the top of a boulder. You don’t want to use surface mount brackets/plates on trees because it’s not the correct hardware for a tree mount. (See Tree Mount Brackets)

Gutter Mounts

Gutter mounts allow fixtures to be suspended securely atop a gutter for illuminating chimneys, weather vanes, cupolas, dormer windows, architectural elements, etc. You can also use this as a stand-off bracket for up lights and down lights. There is no junction box so it’s recommended to use this type of bracket with a heat shrink butt splice rather than a twist-on connector.

Tree Mounts

Tree mounts are small junction boxes that use hanger bolts to keep the box away from the tree bark. A hanger bolt is a wood screw on one end, and a bolt on the other. The wood screw goes into the tree, while the junction box slides over the bolt end and locks in place with two nuts. As the tree grows it will grow up the screw, but it should not be allowed to grow around the junction box. Depending on the growth rate of the tree, the screws will need to be backed out periodically (every year or two?) so that the tree doesn’t girdle around the hardware. Recently King Innovation introduced a threaded spike tree mount that allows for easier hardware adjustments.

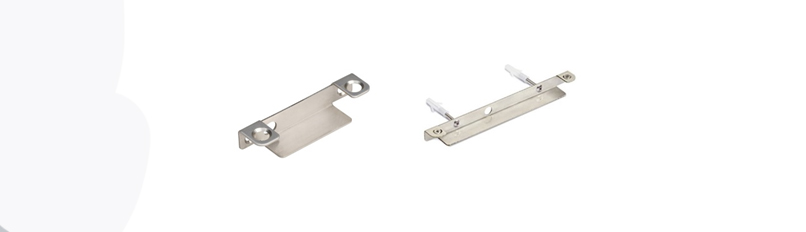

Hardscape Fixture Mounts (removable)

Most major manufacturers offer hardscape lights now, and there are a few different configurations to allow for installation under a capstone (new construction), screwing into the top stone course (just under the capstone for retro-fit projects), screwing into handrails, etc.

Underwater Fixture Mounts (can use in or out of water)

Underwater fixtures are frequently wedged into place between rocks so they don’t always need a mount, but when they do there are multiple options. These include weighted bases, stainless steel brackets, and removable brass bases. These accessories are typically fixture-specific.

Risers, Elbows, & T’s

These accessories give you more flexibility with any of the half-inch threaded mounts above by allowing you to elevate/extend, turn or even connect two fixtures to a single mount with the “T” shown below.

So as you can see from the myriad of different mounts and accessories that are available, it gives lighting designers a number of choices to help address whatever mounting needs come up. Beyond all of the products that manufacturers already make available, in the rare instance that you need a custom bracket made, every city has metal shops that can create whatever you need.