Some time ago now, most the HDPE industry switched from making turf poly from 3608 resin and began using 4710 resin and now all manufactures except Centennial use 4710. What does this mean, and why does it matter?

Centennial has the ability and machinery to run multiple resin compounds since HDPE is they they do. They continue to make turf poly from 3608 resin because they understand it is the best product for the job. Why? Because it coils better, is more flexible, and less susceptible to kinking. What the 4710 poly manufactures can do is give their product a “higher” pressure rating, even though it has the same ID and wall thickness.

Example:

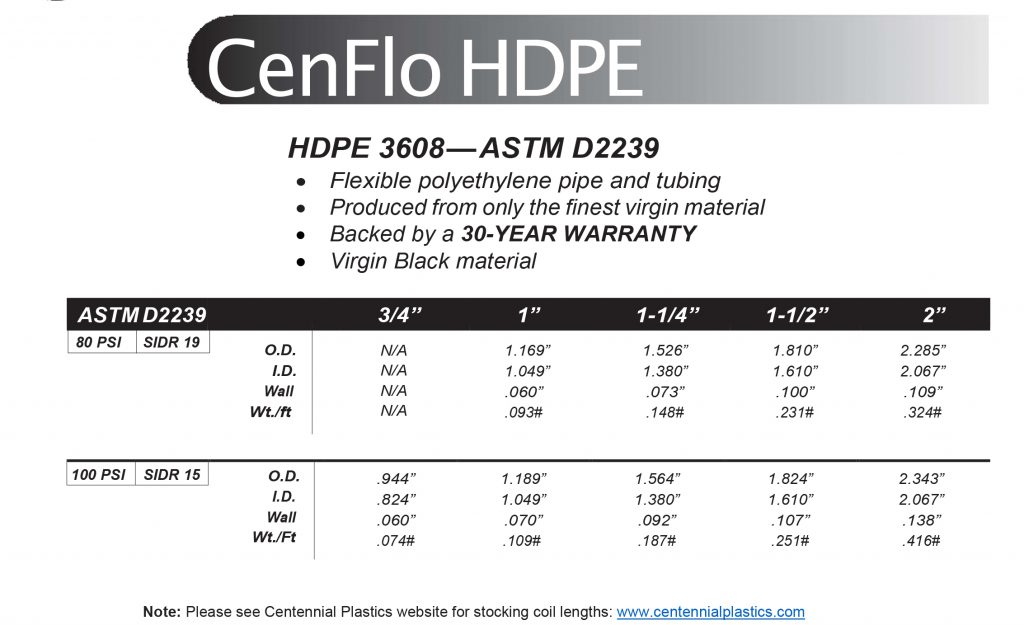

- 1″ (3608) SIDR 19 has a 1.049″ ID, wall thickness of .060″ and weighs .093# per ft (27.90# per 300′ coil) and is rated @ 80 psi

- 1″ (4710) SIDR 19 has a 1.049″ ID, wall thickness of .060″ and weighs .102# per ft (30.60# per 300′ coil) and is rated @ 100 psi

Both products have the SIDR 19 rating, both have the same wall thickness, but the denser, heavier 4710 resin gets a slightly higher pressure rating, but gives up some the more desirable properties of the 3608 Centennial Poly.